Success Stories — Supply Chain

On Supply Chain front, Logimaxx has built a team of cross-industry supply chain experts to bring in-depth knowledge of best practices from 3PL, Automobile, Beverage, Chemical, Defense, Food, Healthcare, Hi-Tech, Manufacturing, Retail, and Utility industries to our clients. Here are some example samplings of success stories from Supply Chain engagements:

Our consultants have performed many supply chain strategy studies across multiple industries. Our consultants have recently worked with a major office supply manufacturer and distributor in North America. The key objective for this engagement was to develop a new distribution strategy in order to optimize the service and delivery processes. Part of the scope was to look at the “End-to-End” supply chain flows for both physical materials and information streams.

Develop strategic plan for logistics and distribution operations

- Creating a baseline scenario to represent current service and financial performance

- Evaluation of distribution warehouse strategy to:

- Understand appropriateness of 3PL facilities and their locations and performance

- Understand the cost and service tradeoffs of current vs future distribution facilities

Demand Analysis to include

- Current customers in geographic areas

- Business density in North America, Central America, South America, and Europe

Evaluation of high level transportation strategy to

- Quantify the performance of inbound and outbound freight costs

- Determine the impact of outbound transportation service windows and their impact on inventory levels

Alternative Scenarios to include

- Optimization scenarios that will evaluate and trade off overall performance, service and costs (warehousing, transportation, IT and other)

- Evaluate high level current performance measurements and alternative performance for the future state model.

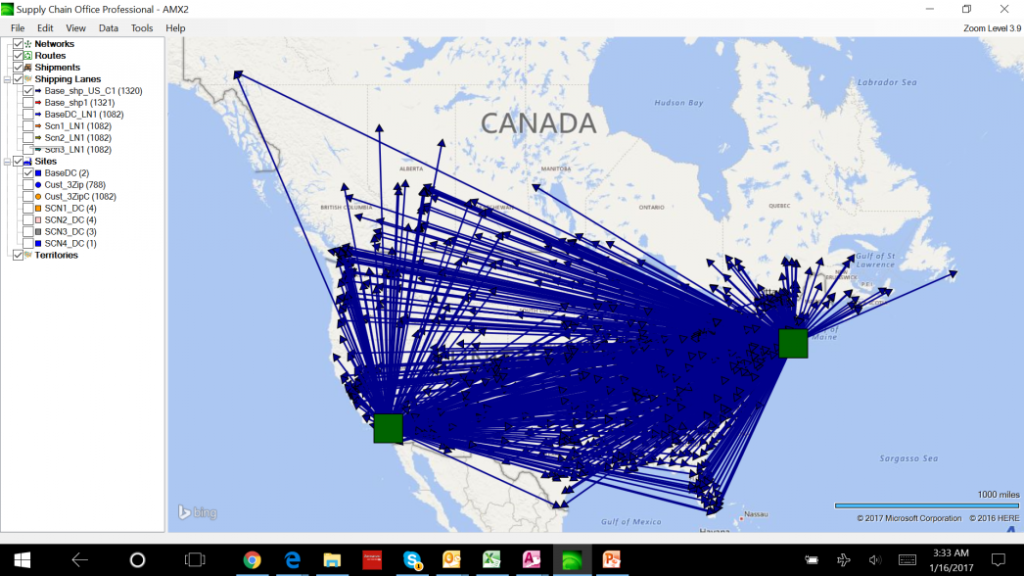

Baseline model snapshot.

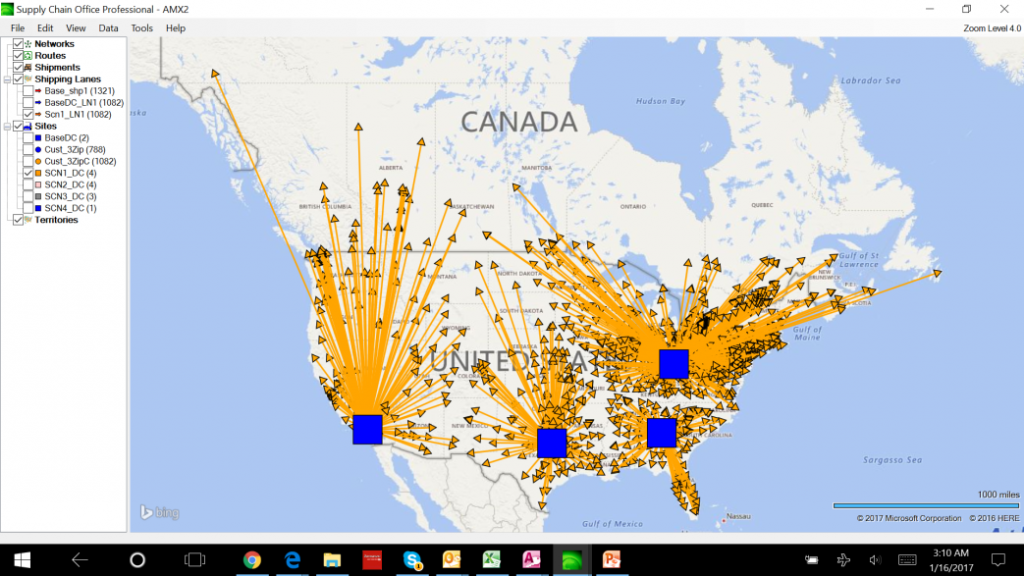

An example of the scenarios evaluated as part of the analysis.

- Outbound average service radius improved from 580 to 240 miles

- Overall Logistics costs improved by 18%

- Inventory turns improved from 4.7 turns to 9 turns

Our team has experience is using state of the art Network Strategy tools such as Llamasoft, CAPS Supply Chain Designer, I2 technologies, Supply Chain Office Professional and many more.

Our consultants have also performed multiple studies to support demand planning and inventory management. In one such study, our team was working with an Industrial Product Vendor (IPV) supporting an Army Depot in Pennsylvania. The key objective for this engagement was to develop a demand planning and Inventory strategy to support

3400 IPV supported parts. Before our team was involved, the client had commissioned a major demand planning vendor (a fortune 50 company) to help support the operation. With 45 days remaining before the operation kickoff, only 1600 (out of 3400) items were available in the warehouse while the software recommending very high inventory to support 99.7% service level requested by the Army Depot.

- Help develop Bi-weekly demand planning to support ongoing demand

- Minimize Inventory obsolescence

- Develop an alternative demand planning and inventory policy solution

- Understand the factors leading to high inventory levels

- Assist the technology vendor with analytical support to help bring in remaining items on contract

- Demand Analysis to include regular demand and project specific demand to support one time installations

- All 3400 items stocked 1 week before the operations kickoff

- Alternative demand planning solution that met service levels as prescribed by the client

- 11 Inventory turns while maintaining 99.75% service level

- Ongoing support for running bi-weekly recommended buys for period of 5 years

As part of this engagement, our team built a predictive analytics platform to support demand planning and inventory policies. This platform includes interactive visualizations at item level detail.

As a part of third party logistics team, our team members have performed many studies related to fleet management. This included tactical planning of fixed routes (milk runs) for certain companies such as major beverage manufacturer where the weekly order profile had a level of consistency. Then there were projects such as a manufacturer of mailing machines where the demand constantly changed during a week. Dynamic routing becomes more valuable in those instances.

In certain scenarios pooling of materials vial larger vehicle and then cross-docking with smaller vehicles and then delivering within smaller service radius becomes cost effective while reducing the service windows.

For instance an automotive company in France near Nantes had many suppliers within a small radius of their manufacturing location. They were using third party carriers and having trouble meeting service windows leading to interruption their manufacturing line. By performing routing optimization using RoutePRO tool we were able to improve the service levels while reducing overall costs by proposing a small fleet of trucks.

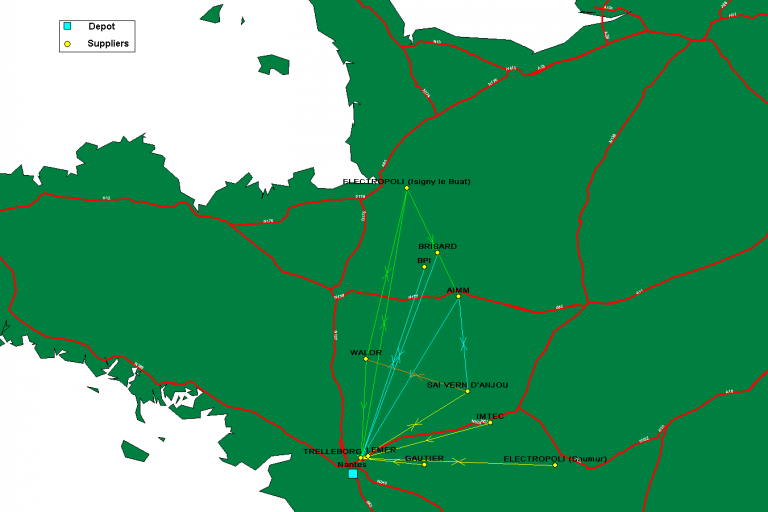

Client’s weekly profile.

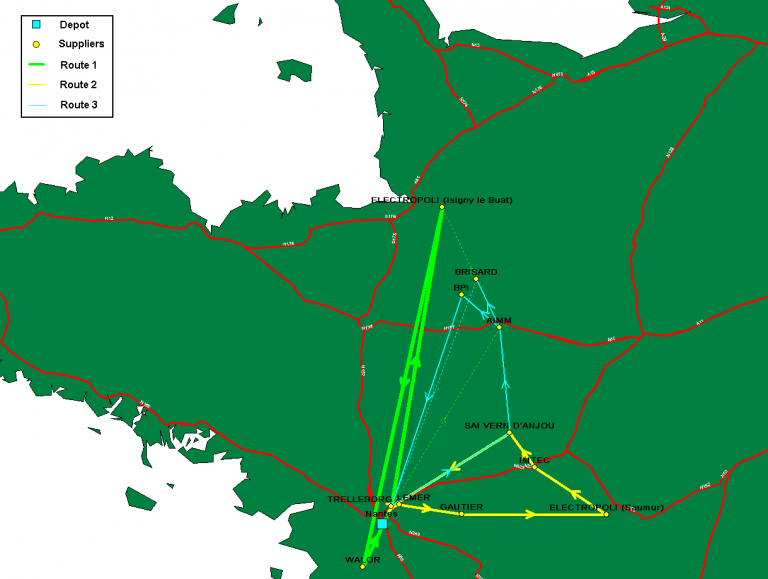

The routing summary of the optimized scenario.

- Dedicated carrier approach to ensure on-time delivery and lower annual cost

- Optimized routing solution with best vehicle utilization

- Flexible solution for changing business needs

- Continuous improvement environment

- Single source management with complete control

Our team has developed similar solution for the largest beverage company which deployed our solution in 40 countries worldwide. Our consultants have performed fleet management studies for at least 15 different clients across the globe.

Our team has experience is using state of the art transportation optimization tools such as Truckstops, RoutePro, Descarte Routeplanner, Paragon, etc.

Impact of Reverse Logistics on Routing Algorithms

presented at INFORMS Conference at Cincinnati, OH in May 1999.

Importance of REMS in the Aftermath of Hurricane Andrew

co-authored with S. Tufekci and A. Albusairi, presented at ORSA/TIMS Joint National Meeting at San Francisco, CA, November 1992. Also appeared in the Proceedings of 1993 International Emergency Management and Engineering Conference at Arlington, Virginia.